These days, multiple construction projects involve demolishing different concrete structures, leaving a contractor with significant amounts of offensive materials to cope with. It is where the issue of concrete recycling arises. Technicians might need a concrete crusher to perform a fragmentation process. See our best crusher machines for concrete processing dealing with cold asphalt, sandstone, and other materials. Keep reading to discover a question – can concrete be recycled?

Can old concrete be recycled?

The truth is that old and unneeded concrete can be recycled and reused in many ways. The recycling process is done in a few stages – breaking, removing, and fragmenting concrete from the determined location. After this, the reusable material called recycled aggregate is created. This material can be utilized as an aggregate in new concrete structures once combined with other virgin materials. Furthermore, recycled aggregate is often an element in a subbase material.

Recycling concrete waste provides a range of good advantages. One of the most significant benefits is cost savings. Instead of transporting the construction debris from the present location, which is quite expensive, recycling can cut back costs associated with expenses for hauling and disposal of construction trash. In addition, individuals can find it not as easy to dispose of concrete and other materials due to specific landfill requirements. Once you consider concrete recycling, you no longer need to bother with compliance with regulations. The environment will also be grateful for concrete recycling instead of its disposal, as this material takes up a lot of space in landfills worldwide. You save energy and thereby make concrete reusable in multiple other applications.

How to crush concrete for recycling?

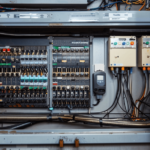

The exact concrete recycling way dramatically depends on the volume and type of your material. In most cases, a building materials company will be engaged in recycling construction materials. After all, this organization will determine whether to recycle concrete on site by using portable crushing machines or transport it to the recycling factory. A standard option is renting or purchasing a mobile rock crusher. Moreover, remember that concrete must be separated from steel. Thus, ensure your crushing equipment features a powerful separator. It will never hurt to consult your materials representative regarding the best method for concrete recycling.

The most widespread concrete recycling method includes a few stages. Some industrial appliances provide jaws, cones, and conveyors to perform the entire recycling process at once. First, large concrete pieces are broken down by using specific industrial machines. Equipment for this purpose usually comes with jaws for material fragmentation. The next stage is removing any contaminating particles from concrete.

Depending on the type of particles, magnets, separators, or other appliances might be involved. Finally, the recycled material is divided into large and tiny aggregates. There is an alternative solution for concrete recycling called pulverization. However, it can be more complex to separate impurities from the material.